Discover the Numerous Kinds of Screen Printing Techniques for Your Next Task

Screen printing uses a diverse array of strategies that can improve any type of imaginative job. From typical techniques like serigraphy to modern developments such as direct-to-garment printing, each approach has its distinct advantages. Specialized choices, including metallic and environmentally friendly inks, introduce even much more opportunities. Recognizing these methods can significantly affect the final outcome. However, the difficulty exists in picking one of the most appropriate approach for details needs and preferred effects. What aspects should one take into consideration?

The Basics of Screen Printing

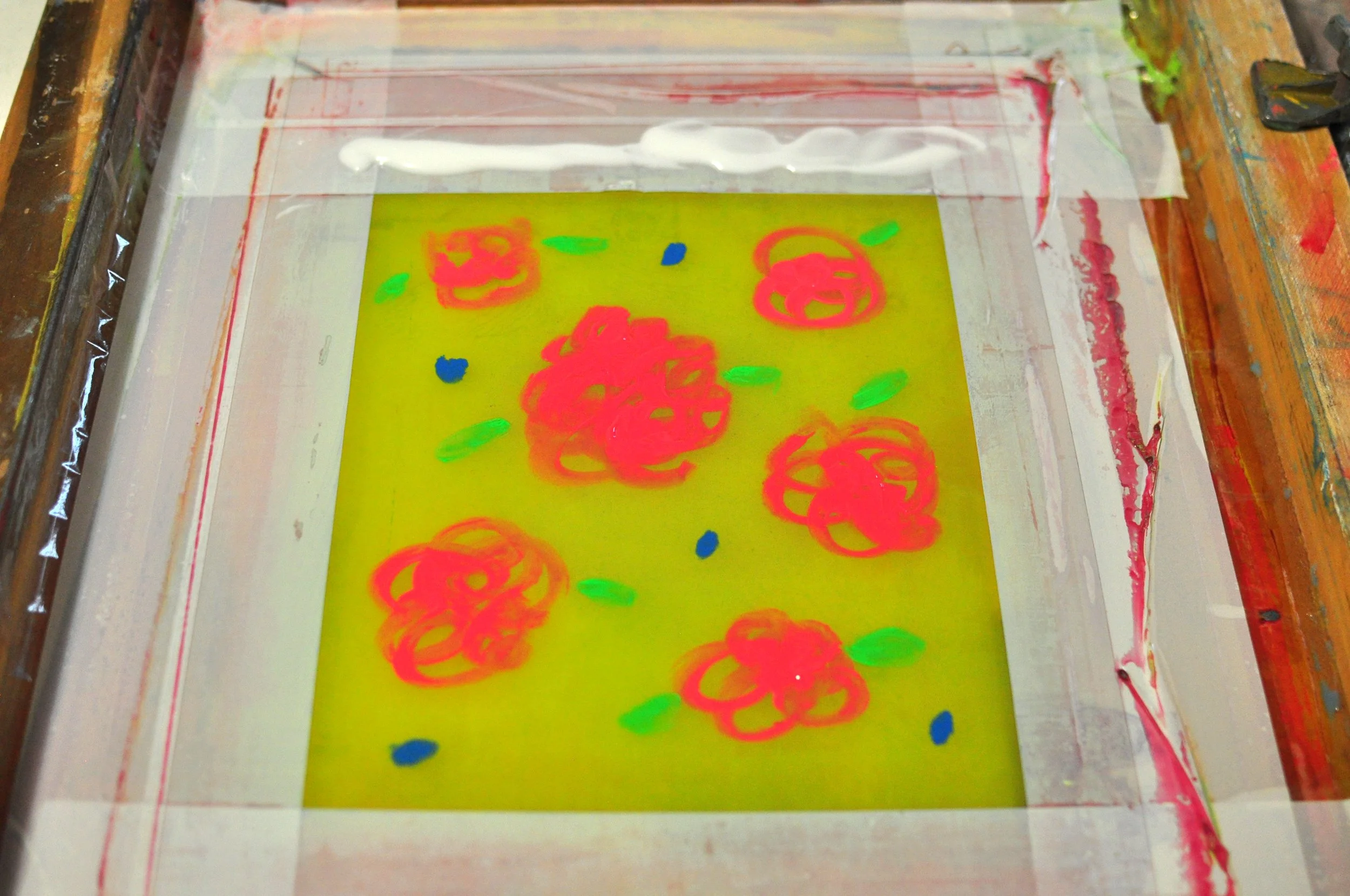

Screen printing might appear complex, it is fundamentally a simple process that entails transferring ink via a mesh screen onto different surface areas. The technique starts with the creation of a stencil, which specifies the layout to be published. This pattern is connected to a mesh screen, commonly made of polyester or nylon. Once the pattern remains in place, ink is put on the screen and pushed via the mesh using a squeegee, leading to the desired pattern being published on the underlying material.

Screen printing can be executed on a large range of substrates, including fabric, paper, and plastic, making it a flexible choice for numerous jobs. The procedure permits intricate layouts and dynamic colors, making it preferred in industries such as fashion, art, and advertising and marketing. Understanding these basics equips people with the fundamental knowledge needed to discover even more sophisticated methods in screen printing.

Conventional Screen Printing Techniques

Conventional screen printing techniques have actually been used for centuries, preserving the workmanship and artistry of this technique. This approach uses a mesh screen to transfer ink onto a substratum, such as material or paper, enabling lively and resilient designs. The process begins with developing a stencil, which obstructs certain areas of the screen to control where the ink will certainly be used.

One preferred technique is serigraphy, frequently utilized for imaginative prints and restricted versions. An additional is the usage of water-based inks, which are environmentally friendly and supply a soft feeling on textiles - 10:9 Design Company. In addition, standard techniques can consist of hands-on printing, where craftsmens use ink with a squeegee, making certain precision and interest to information

These techniques stay valued in the industry for their responsive high quality and the distinct structures they generate, appealing to both customers and designers who appreciate the heritage of screen printing.

Digital Screen Printing Innovations

As the demand for faster production and modification in the printing industry has surged, electronic screen printing developments have actually arised as a game-changer. This modern technology blends traditional screen printing techniques with digital procedures, permitting rapid prototyping and elaborate layouts that were previously difficult to attain. One substantial development is the introduction of direct-to-garment (DTG) printing, which helps with top notch, full-color prints on numerous fabrics without the need for displays. In addition, innovations in ink solutions have actually brought about environment-friendly alternatives that keep vibrant colors while reducing environmental impact. The usage of automated systems further improves production, reducing labor prices and improving precision. These advancements not only satisfy little set orders and personalized styles however likewise enable quicker turnaround times, making them optimal for businesses concentrated on conference consumer demands in a hectic market. Digital screen printing, consequently, represents a necessary evolution in the domain name of printing techniques.

Specialized Screen Printing Methods

Exploring specialized screen printing approaches discloses a diverse variety of techniques that press the boundaries of creativity and functionality in the printing sector. Among these, glow-in-the-dark inks give a distinct aesthetic result, making styles come active in low-light conditions. Metallic inks, understood for their sparkling coating, include a touch of high-end to published materials. One more innovative approach is discharge printing, which gets rid of dye from the fabric instead of adding ink, causing a soft, vintage feeling. High-density printing creates a raised structure externally, boosting responsive interaction. Furthermore, water-based inks are acquiring popularity for their vibrant shades and reduced ecological influence. Each of these specialty strategies caters to certain layout requirements, enabling artists and brand names to create standout items that resonate with their audiences. By description leveraging these approaches, companies can elevate their screen printing projects to brand-new heights, ensuring remarkable impressions.

Eco-Friendly Screen Printing Options

Green screen printing options are obtaining traction as the industry moves in the direction of sustainability. Lasting ink selections and making use of naturally degradable products are vital elements in minimizing the environmental impact of the printing procedure. By adopting these techniques, screen printers can add to a more lasting future while preserving high-quality outcomes.

Lasting Ink Options

Biodegradable Materials Use

As the screen printing market advances, the unification of eco-friendly materials is ending up being increasingly crucial for ecologically aware methods. Designers and producers are currently dig this checking out inks and substratums made from natural, eco-friendly sources that disintegrate a lot more successfully than standard equivalents. These naturally degradable alternatives reduce plastic waste and lessen ecological effect, aligning with the expanding need for sustainable items.

Usual instances consist of water-based inks and organic cotton fabrics, both of which reduce damaging chemicals and promote eco-friendliness. Brand names that take on these products usually improve their market charm, bring in customers that focus on sustainability. As understanding of ecological concerns proceeds to climb, the shift in the direction of biodegradable products in screen printing is likely to get momentum, fostering a greener industry standard.

Selecting the Right Strategy for Your Job

Just how can one determine the most appropriate screen printing strategy for a particular task? The decision depends upon numerous variables, including the product to be published on, the intricacy of the style, and the desired production quantity - 10:9 Design Screen Printing Texas. Direct-to-garment printing is ideal for detailed layouts with various shades, while standard screen printing excels for larger runs of simpler graphics.

In addition, consideration of the end-use of the published product is important. For outdoor applications, methods that offer resilience and weather resistance, such as plastisol ink, may be liked. On the other hand, environmentally-conscious tasks may take advantage of biodegradable materials or water-based inks.

Inevitably, understanding the job's unique needs enables an enlightened choice, guaranteeing both visual allure and functional longevity. By assessing layout intricacy, product compatibility, and production range, one can properly select the most proper screen printing technique to satisfy their job's objectives.

Regularly Asked Questions

What Is the History of Screen Printing?

Screen printing stemmed in old China around 1000 ADVERTISEMENT, evolving through Japan and Europe. By the 20th century, it ended up being preferred in business art and style, revolutionizing how designs were created and dispersed around the world.

How Do I Prepare Art Work for Screen Printing?

To prepare artwork for screen printing, one have to guarantee high resolution, utilize an appropriate color mode, develop separate layers for every shade, and convert message to outlines, assuring compatibility with the printing process and desired outcome.

What Materials Are Best for Screen Printing?

The very best products for screen printing consist of high-quality inks, resilient displays, smoking area signs to print and ideal substratums like cotton, polyester, or blends. In addition, making use of appropriate emulsion and mops can enhance the printing procedure and final results.

Can I Screen Print in the house?

Yes, screen printing at home is feasible. With the best materials, configuration, and methods, individuals can produce top notch prints. Mindful factor to consider of work area and devices is essential for successful outcomes.

What Prevail Errors in Screen Printing?

Usual blunders in screen printing include improper exposure times, poor ink consistency, imbalance of screens, inadequate cleansing of products, and disregarding to examine prints. These mistakes can compromise the quality and precision of the end product.

Screen printing might seem complex, it is basically a straightforward procedure that entails moving ink via a mesh screen onto different surface areas. As the demand for faster production and customization in the printing market has risen, digital screen printing technologies have actually emerged as a game-changer. Discovering specialty screen printing techniques exposes a varied array of techniques that push the boundaries of creativity and functionality in the printing industry. The ideal products for screen printing include top quality inks, resilient screens, and ideal substratums like cotton, polyester, or blends (10:9 Design Texas). Common blunders in screen printing consist of incorrect exposure times, poor ink consistency, misalignment of displays, inadequate cleaning of products, and ignoring to evaluate prints